6 Questions to Ask Your Printer About Green and Eco-Friendly Printing

Check out my interview about eco-friendly and green printing options with Jen Zawistowski, President of JAZ Print & Promo in Boulder, CO

Last year, I took a Green Graphic Design course where I learned a lot about the impact that paper manufacturing and commercial printing have on the environment. As a graphic designer, this is a big deal to me. Most of the projects I design for my clients are intended for print, and if I’m not being deliberate about which materials are used during the process, these pieces will eventually become just another piece of trash in a landfill. Chances are if you run any sort of business or nonprofit, you’re printing business cards, postcards, promotional materials and annual reports, it’s an essential part of operating. It’s important that we’re mindful of our impact when producing these materials.

Navigating eco-friendly or “green” printing can be a frustrating task, which is why I wanted to bring in an expert from the inside. I did an interview with Jen, the president of JAZ Print & Promo in Boulder, CO. and got the inside scoop on eco-friendly printing.

First, I asked Jen what questions consumers can ask their printer to make sure they’re getting a truly eco-friendly product or at least the transparent information they need to make a decision. She says it’s important to create a trusting relationship with your print manufacture and talk to them at the conceptual phase of your marketing campaign and have them assist in creating the green product you like.

What to Ask Your Printer About Green Printing

1. Do you use recycled paper? If so, what is the post-consumer waste content of the paper?

I designed Earth Day postcards and had them printed on 100% recycled paper.

Ask what the PCW (post-consumer waste) content is of the paper, not just recycled content. Paper mills are allowed to consider paper waste from inside the mills put back into the slurry as recycled material. If you really want paper made from trash, ask for PCW content. Sometimes paper will be listed as 30% recycled (10%PCW), meaning only 10% of the recycled content is from trash, the rest is from internal mill waste.

2. Do you offer alternative, tree-free paper?

Ask and learn about alternative papers, materials and systems to get the most impact for your dollar. If you’re willing to spend a little more to use a sustainable option, ask about alternative papers made from renewable, faster-growing plants such as: bamboo, cotton, hemp papers & kenaf.

3. What kind of inks do you use?

Double check that your printer is using some form of vegetable-based inks. Most print shops use vegetable-based inks now. Historically, printing ink was produced using petroleum.

4. Is the project using any coatings or laminations?

Most coatings and laminations are not recyclable. Often clients want fancy spot UV coatings or soft-touch laminations, and these items are often put in recycle bins, yet are not truly recyclable. Additionally, stay away from tear-resistant, ear-proof materials or waterproof material, most are not green.

5. Which document size can I use to waste the least amount of paper?

Stick to standard sizes when using the digital printing process. Projects that have graphics or images that bleed off the edge require extra paper to be trimmed and wasted. Rounded corners also produce a minimal amount of waste.

6. Are your products and printing services sourced ethically and locally?

In the United States, we have a higher standard for worker health and the environment than overseas mills and manufacturers. Costs of raw goods and materials made in USA are higher, but that is to cover minimum wages, health insurance, workman’s comp, disability, as well as regulations for OSHA that all print shops must follow. Overseas these regulations are not in place. Although the product is cheaper, there is a higher cost in human illness in production plants, more potential for waste dumped in the ocean and higher levels of CO2 emissions from shipping and transportation.

I am a huge supporter of finding items Made in USA. Additionally, if you’re using an online printer, know where your goods will actually be produced – some budget online printers will offshore their projects to maintain cheaper prices. When possible, use local printers and maintain open communication about sourcing materials.

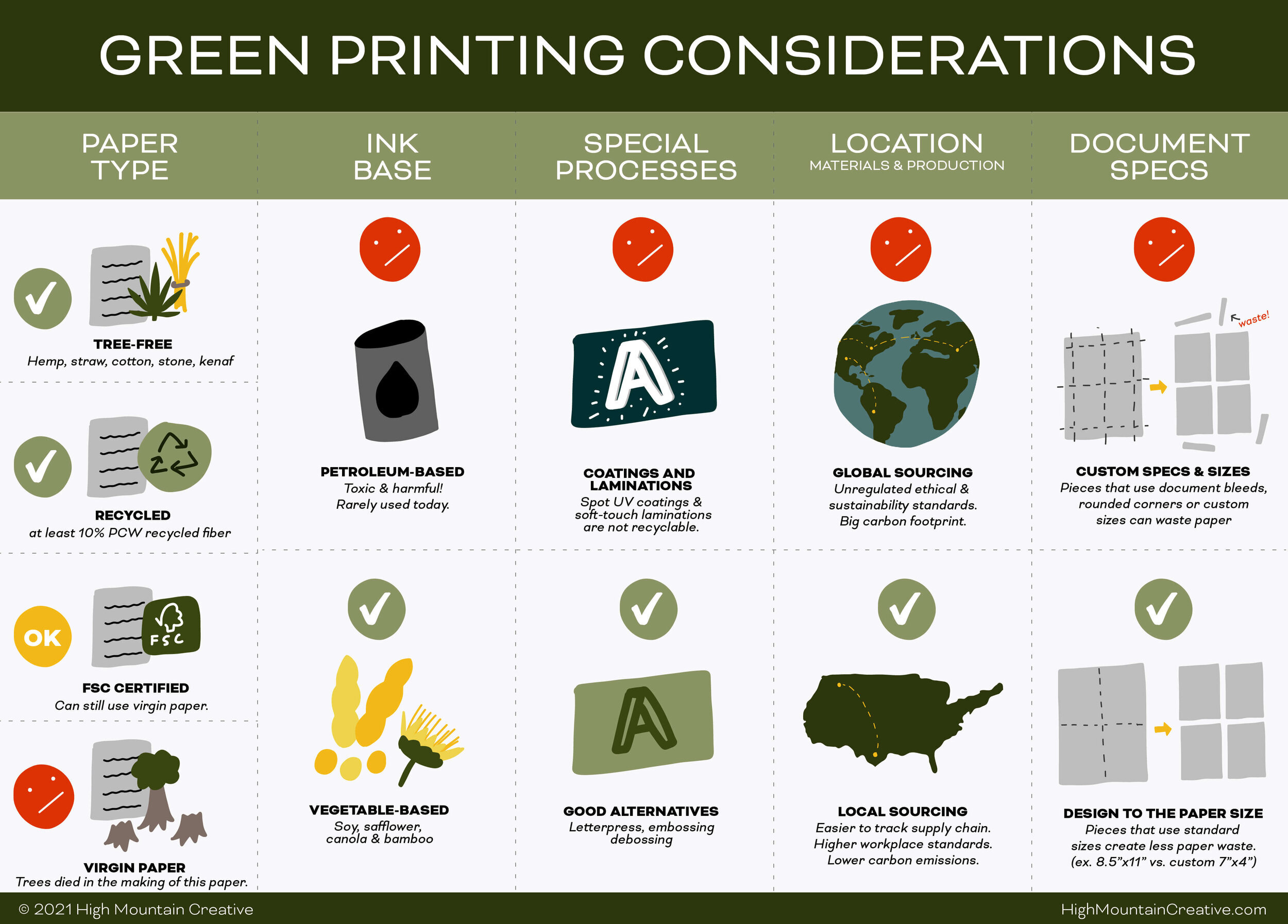

When looking for a green printer, consider these five areas: paper type, ink base, special processes, location of material sourcing and production and document specs.

I also had some more specific questions for Jen about her experience with green printing at JAZ and the current and future state of the green printing industry.

Margo: What green printing techniques have you implemented at your print house?

Jen: At JAZ Print & Promo we assist clients in choosing materials that have less impact on the environment. For printed items, we like to suggest papers that have at least a minimum of 10% PCW recycled fiber mixed in.

This self-promo was letterpress printed on seed paper. Seed paper is an awesome alternative to virgin paper because instead of being thrown away or recycled, it can be planted to grow wildflowers.

M: Unfortunately, most papers that have higher recycled content still cost more than virgin sheets. This deters a lot of people from making the change to recycled paper. Can you talk a little about that?

J: Many customers want to print on a very white smooth sheet and the steps to create this kind of look and feel from recycled material have a higher cost. For large print jobs, this can increase budgets upwards of 20-30% in material cost alone. We have many clients that have written into the bi-laws to use a certain percentage of recycled content for all marketing materials.

Paper using Forest Stewardship Council (FSC) Certifications can add hundreds to thousands of extra dollars to a print project. Print shops need to re-certify each year and pay the fee for licensing. Paperwork to prove chain of custody from cutting trees to printed postcards adds a lot of cost to projects. This contributes to the higher cost of using recycled paper.

M: What are the latest trends in Green Printing?

J: I’m excited to see more alternative materials coming into the market for base materials as well as for inks. Most ink manufacturers have moved away from petroleum-based inks and use some form of vegetable ink such as soy, canola, safflower & now bamboo. Some of the newer inks take time for pressmen and equipment to learn to use and adjust ink densities and color balance.

With digital printing equipment becoming more and more sophisticated, it cuts down on the need for metal plates, offset inks and paper waste for setting up commercial presses for offset printing jobs. Typically, about 100-200 sheets of paper are used per color to set up an offset press. Digital printing removes all of that setup and waste. You can run small quantities and not have the set-up time, cost and material you would with offset printing.

I asked Jen about her favorite eco-friendly project. This was something she produced for a Deuter USA display at REI for kid carrier backpacks. The client wanted to produce something durable, yet environmentally friendly. Typically signs like this would use coroplast, a product like corrugate-like material, made from plastic, in this case we used a product called Flacon Board. It is very strong, rigid, SFI certified, made from renewable forests and fully recyclable. Deuter chose to spend more money on the material to keep to their values in supporting the environment and having a recyclable product going out nationally. (Note: High Mountain Creative was not involved in this project.)

M: Bamboo ink! Now, that’s pretty cool. My dad worked in the family ink business for 44 years, I’ll have to tell him about that one! We’ve come a long way since petroleum inks.

M: Greenwashing is becoming a big problem in the green movement. Are there any printing practices that are marketed as green that aren’t truly green options?

J: Items, such as business cards, with lamination and UV coatings, are not recyclable. I’ve seen many items printed with labels that say “made from recycled materials” with the recyclable logo on them but once coated, they are no longer recyclable. All paper, if not coated or made with added synthetics, like waterproof papers, can be recycled.

M: In the past five years, how have you seen consumer demand for green printing change?

J: Clients are asking more questions. They’re becoming more aware of options open for them to use. What the industry needs now is a consumer/purchaser movement to happen in order to increase demand. It’s a chicken and egg situation. There’s not enough demand yet to make recycled & green materials less expensive or comparable to virgin sheet options. We are slowly working toward that in the industry, but we need more and more clients to want to take the step and make this part of their identity and brand.

“What the industry needs now is a consumer/purchaser movement to happen in order to increase demand. It’s a chicken and egg situation.”

M: What do you think will be the next biggest trend or innovation in green printing?

J: Customers want to make more of an impact by having an item that’s going to be noticed or held onto rather than immediately thrown out. I’ve been seeing more thought put into the design process to create a totally out-of-the-box item. Things like using special papers and techniques to make imagery stand out. We are printing shorter runs but higher quality. I foresee more of this happening in the future.

M: How can clients message their green printing efforts to their audience?

J: If clients are going to spend the extra money to purchase and print with recycled materials, I feel it is imperative for the design and messaging to be passed to the end receiver. The general public can’t tell the difference between a virgin sheet of paper and one that has a high recycled content just by the look and feel alone. The messaging needs to be added to the marketing material, mentioning the recycled content, if FSC certified, the percentage of PCW in the paper and why using recycled content is important for the company. This should be part of the overall branding and messaging from company to consumer.

Jen Zawistowski is the President of JAZ Print & Promo in Boulder, CO.

www.JAZprintandpromo.com

You can contact her at jen@jazprintandpromo.com